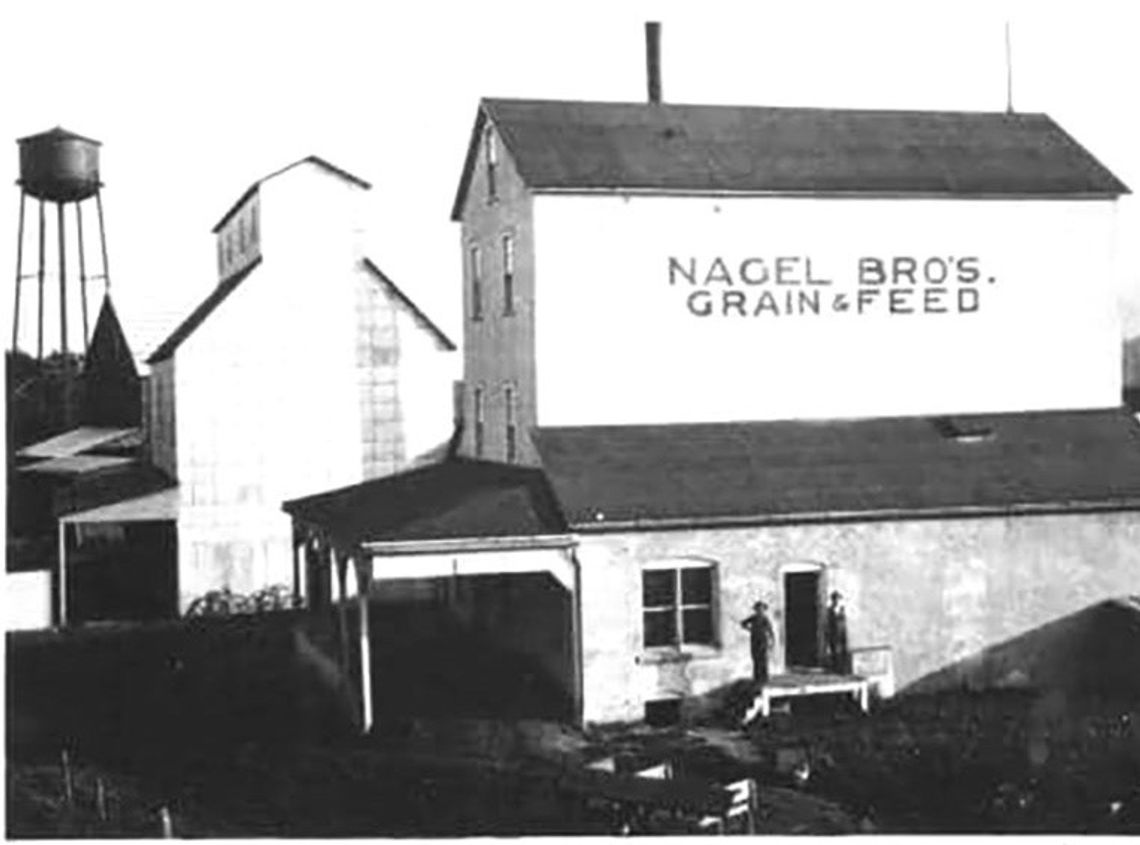

Everyone has heard of Quaker Oats Company … many of us Baby Boomers grew up on mom’s “oatmeal.” The company that was the precursor to Quaker Oats and sold the patent to Quaker was from Bushnell, Illinois. The Nagel brothers were the first to invent a process of making rolled oats without having to steam the oats. The oats were rolled to flatten them into a flake.

The Nagel Roller Mills was founded in the early 1900s by John and Henry Nagel, who were born in Germany. The rolled oats were first manufactured in the Nagel Roller Mills building on Davis Street.

C.S. Norcross Blacksmith

The name Norcross has been synonymous with Bushnell for as long as most of us can remember. The story of C.S. Norcross began in Boston, MA, with a violin teacher named Samuel. Samuel’s bad allergies led him to Pennsylvania and there a son was born, who was named after a famous violinist Camillo Sivori.

Another move took the family to Quincy, Illinois, where C.S. learned the blacksmith trade. He settled in Liberty and married. The Norcross family eventually moved to Walnut Grove, Illinois and a second son was born. C.S. Norcross’ blacksmith shop gained a fine reputation and business was good.

C.S. Norcross was also an inventor. In 1891, he invented a five-prong hand garden cultivator, which totally changed his career and life. He got a patent on the tool and the C.S.

Norcross Company was born. Norcross probably had a vision that inventing farm equipment might be an easier way of life than the tiresome occupation of blacksmithing.

Norcross had the task of changing his blacksmith shop into a factory. To build his cultivator he needed jugs, dies, heating surfaces, grinders, steel, malleables, handles, bolts, paint, etc. He was able to buy grinders and a trip hammer, but had to create the rest of his machinery from scratch.

He had the backing of the First National Bank in Bushnell. His brother, Samuel, soon joined him in the business.

To power the Norcross factory, C.S. used two horses working side by side, and later, he utilized an upright 6 H.P. gasoline engine. Finally, C.S. bought a 16 H.P. steam engine from a sawmill on Spoon River. LeRoy, son of C.S., had joined the family business and had the job of getting up early to have steam available by 7 a.m.

Steel was delivered once a year from Pennsylvania.

It was shipped in heavy wooden boxes and literally “dumped” off of the train about 50 feet from the shop.

The Norcross workers then used wheel barrows to haul the steel rods to the factory.

The Norcross Company was ahead of its time in the field of marketing. Each spring they loaded up all of the completed tools and headed to the countryside and small towns. The goal was to enlist additional salespeople in different townships and counties. In 1895, LeRoy went on the road and traveled for five years by train and through Illinois, Indiana, Ohio and Michigan. LeRoy hoped to sell 10,000 cultivators and he did indeed reach his goal.

In 1904, C.S. Norcross accepted a gift of some land at the corner of Dean and Davis Streets. In 1906, the first Norcross building in Bushnell was constructed of concrete blocks. The move was a good one for the Norcross Company, as there was a reliable railroad shipping facility and more available laborers. In 1905, Norcross received its first order from a ‘jobber’ (wholesaler). The order was for 600 cultivators from Wisconsin. Wagons would be used to transport the orders to the freight depot on East Main and Hurst Streets. Eventually, Norcross products would fill entire train cars.

By 1913, LeRoy began advertising overseas. The first orders were mostly from Australia; however, customers began to surface from England, France, Germany, Belgium, Poland, New Zealand, South Africa and Scandinavian countries.

When the national average for all U.S. manufacturers’ export sales was about 10 percent, Norcross’ foreign sales grew to 25 percent.

Norcross During World War I & World War II The beginning of World War I saw families patriotically planting gardens, or “Victory Gardens.” Soldiers overseas would see the Bushnell- made tools for sale in European stores and become homesick. But when the war was over, people lost interest in gardening tools. For about three years Norcross had practically zero sales, as their wholesalers had as much or more inventory than they needed. Luckily, Norcross Company had some money put away.

On October 17, 1928, C.S. Norcross died. Many local manufacturing businesses began to close with the Great Depression. Soon Norcross was the only major employer in Bushnell still open.

In 1932, LeRoy’s son, Charles E. Norcross joined the company, and two years later, Charles hit the road to meet with current and potential jobbers. In 1936, Charlie developed a new method to manufacture steel hand pitch and manure farms. This called for more equipment and expansion of the factory.

In 1941, with the new equipment they had acquired, Norcross was able to help the war effort by making parts for military equipment. This put Norcross in the forging business. Charles Norcross would later reflect that the farm people came to the rescue when the young men went off to war.

Older farmers and young boys would farm all day then come work for the war effort at Norcross at night. Also, for the first time, Norcross began to hire women.

When the war ended in 1945, Norcross gradually changed back to civilian goods. During the 1950s, 60s and 70s, Norcross continued to expand their forging business and product line. The business was sold in 1977, 1985 and again in 1992.

Vaughan and Bushnell Manufacturing Company Alexander Vaughan, founder of what for many years was known as Vaughan and Bushnell Manufacturing Company, was born in 1826.

Alexander’s father was a blacksmith, a trade the son also learned. Alexander had an entrepreneurial streak, and after the Civil War he improved the design of Augers used for digging post holes.

Vaughan and his wife moved first to Peoria, then to Chicago, where the Chicago Fire destroyed Vaughan's Windy City business. Sidney Bushnell and his son offered financial support, thus beginning the Vaughn and Bushnell partnership. Sanford S. Vaughan, Alexander and Elizabeth’s only son, joined the company in 1886, and Sanford's son, Howard, realized the need for a larger facility.

By fluke, at a dealer show in Chicago, Howard Vaughan found his booth located next to a company from Bushnell, IL: C.S.

Norcross and sons. Norcross was located in Bushnell, Illinois, and the conversation between Howard Vaughan and Charles Norcross naturally turned to the coincidence of names. Impressed by Norcross’ description of the town and its advantages, Howard and other company officers made several visits, and ended up purchasing the former Brant Building in Bushnell in 1940.

Limited manufacturing commenced in Bushnell in Fall 1940, and was gradually expanded during World War II. The company was by then making hammers, chisels, punches, wrecking bars, pliers and more.The town location and ample labor supply proved so favourable that in 1950, it was decided to consolidate all manufacturing operations at Bushnell.

Howard’s noted inven- tion was the 15” flat prybar, known internally as the B215 as its 2” wide and 15” long! It is rumored to be named the “Superbar” by his wife. To this day, its Vaughan’s (now made by Marshaltown) #1 selling item.

Farm Implement News Buyer's Guide (1908)

Ad from Hardware catalog in 1951

Five generations of Vaughans would make their mark on the Vaughan & Bushnell plant through the years up until May 2024 when Marshalltown Manufacturing, from Marshalltown, IA purchased the Vaughan & Bushnell Mfg. Co. This purchase, and investment by Marshalltown, saved the storied factory and Bushnell institution from closing its doors forever.

What hasn’t changed over the years is the Vaughan name and its dedication to quality. Vaughan tools continue to be made in Bushnell with the highest quality and exceptional attention to detail under Marshalltown Manufacturing.

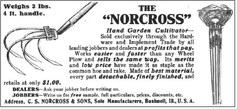

Ball Bros. Buggies and Wagons Ira Daniel Ball was born in 1818, in Newark, New Jersey. In 1831, his father Jonathan moved the family to Newark, Ohio. Ira had received not only a common school education for that time, but he also learned about the art of carriage and wagon building.

In 1861, Ira, who now had a family of his own, moved to Bushnell and opened a wagon and carriage works at the corner of East Main and Gridley. Ira would father 11 children, with two babies dying in infancy. When his sons grew old enough, four of them were sent back to their uncles in Newark, Ohio, to learn about the manufacturer of wagons and carriages.

Through the 1890s and early 1900s, the business excelled. Ball Bros. workmanship was second to none. Bicycles were added to the product line. The Balls added auto sales, service and storage in the north building. Some of the Ball family moved to California in 1915, selling the business. One son, James, bought back the automobile agency. James’ son, George, joined his father when he got back from the war in 1919. They sold Buick, Packards, Oldsmobiles and Studebakers until the Great Depression forced them to bankruptcy in the early 1930s.

In the 1920s and 1930s a dance hall was operated on the second floor, known as Ball’s Hall. It would eventually become the Bushnell Recreation Center until the present Recreation and Cultural Center was built in 1976.

Founded by Karl and Eileen Raushert and now growing into the third generation, Midwest Control Products (MCP) now resides in the Ball building. According to the Midwest Control Products website, Midwest products include linkages (ball joints, clevises, clevis spring pins, spherical rod ends and yoke ends), flat bar fabrications, tube fabrications, upset forgings, wireforms, laser cutting sheet/tubing, contract powder painting, and push pull cables. Today, MCP ships to over 10,000 different OEM's (original equipment manufacturers) and distributors worldwide.

Read more about Bushnell’s History in upcoming editions.

Credit: A Look Back... Bushnell, Illinois 1854-2004. A Sesquicentennial History (Rollene Storms and Peggy Hood)

One of the earliest wagon and carriage builders in Bushnell, Illinois and the immediate predecessor to Ball Bros. was Ball & Sons. The company was launched near the close of the Civil War and remained in business for almost a half century. It closed down in 1914 after selling its assets, the building that the business had occupied became a dealership for the Packard automobile. This reach plate dates to around 1910. Photo courtesy of Wheels That Won the West Archives, LLC